Details

Rotogravure printing machine for aluminum foil Worldly WAP

To meet the special demands of aluminum foil printing, Worldly Industrial Co. has developed the best solution for this special printing - the WAP series of rotogravure presses. Taking into account the varied characteristics of printing on aluminum foil, Worldly has designed a dedicated press combined with a varnishing unit. The varnishing unit applies the protective varnish after printing, including HSL varnishing. The machine has the ability to print on reverse side of material, doctor blades are installed on both sides to provide printing on the reverse side for any unit.

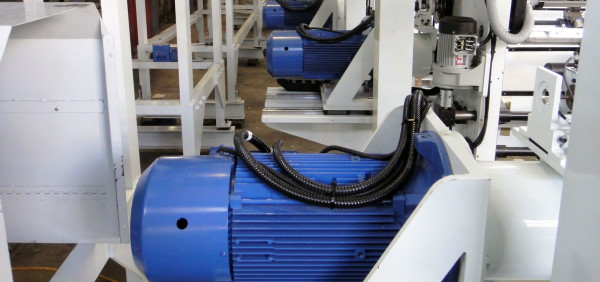

The machine is built on the principle of "electronic shaft", each section is equipped with its own drive with electronic synchronization. This saves changeover time and reduces print waste.

The machine is equipped with a four-zone drying tunnel system, which makes drying the most efficient.

The automatic double shaft unwinder and rewinder are equipped with auto splicers.

The machine is fully controlled by a touch screen computer system with a user-friendly interface, so the operation is fast and efficient. Automatic color register system ensures consistently high print quality and reduces waste.

.

Print units design

Each printing unit has a double-sided squeegee mechanism for reverse printing in any of the following combinations, for example, 3 + 5, 2 + 4, 4 + 4.

.

Inline HSL varnishing

The last varnishing section, together with the drying tunnel, can perform in-line HSL varnishing.

.

Centralized control system allow man power saving

Centralized control system integrated operator HMI, web video monitor, and color registration panel for easy access working parameter and man power saving. Automatic longitudinal and side-lay register control system. High flexibility master mark setting. Also able to save various parameter conditions to job memory.

Latest E.L.S drive technology

All unwinder, in-feed unit, printing units, out-feed unit,, rewinder are individually driven by AC servo motors and drives. The cylinder has direct driven to optimized the ransmission with low mechanical loss. Whole machine automation and tension controlled by high performance PLC system.

Technical data Worldly WAP

- Material width: 800 mm / 1000 mm

- Materials: PET, BOPP, aluminum foil

- Maximum speed: 180 m / min

- Maximum print speed : 150 m / min

- Print sections: 1-12

- Print cylinder: 350 mm - 800 mm

- Material roll diameter: Ø600 mm / Ø800 mm